Listening to the sound of the ocean-special optical fiber and solutions for hydrophones

Sound signal is the only form of energy that can travel long distances in seawater. It uses sound waves as an information carrier to monitor the acoustic characteristics of underwater targets. Advanced methods of resource surveying. our country has more than 30,000 kilometers of coastline and abundant marine resources. In order to defend the sovereignty of our country’s territorial waters and increase the development of marine resources, it has a far-reaching strategy to establish a complete underwater alert system in country’s important sea areas and develop a complete underwater sound detection system.

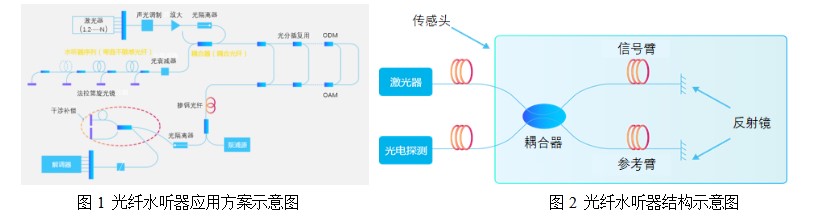

Fiber optic hydrophone is an important component in the underwater acoustic detection system (see Figure 1), it is advanced optical fiber optoelectronic technology and underwater acoustic engineering technology. The combined new product has broad application prospects in marine environment monitoring and advanced underwater acoustic equipment. According to the principle classification, fiber optic hydrophones have intensity type, polarization type, phase interference type and so on. Among them, the phase interference fiber optic hydrophone has become the main object of current research, development and use due to its advantages such as high accuracy, good stability, small size and easy to form an array on a large scale. The phase interference type fiber optic hydrophone is made based on the interference principle of Michelson and Mach-Zehnder, and its interference structure has entered a mature stage of commercialization. The basic principles of the two are the same (as shown in Figure 2). The laser light emitted by the laser is divided into two paths through the fiber coupler: one path constitutes the sensor arm of the fiber interferometer, which receives the modulation of the sound wave, and the other path constitutes the reference arm, providing Reference phase. The two waves return to the fiber coupler after being reflected by the back-end reflective film, and interfere. The interfering optical signal is converted into an electrical signal by a photodetector, and the information of the acoustic wave can be picked up after signal processing.

The key component of hydrophone is the fiber ring wound by fiber. The size of this ring is generally small, the diameter is only 10mm, the macro bending loss index of ordinary fiber is difficult to meet its requirements, and the mechanical reliability of this kind of submarine fiber is higher than that of conventional fiber.

The key component of hydrophone is the fiber ring wound by fiber. The size of this ring is generally small, the diameter is only 10mm, the macro bending loss index of ordinary fiber is difficult to meet its requirements, and the mechanical reliability of this kind of submarine fiber is higher than that of conventional fiber.

1. Special hydrophone Optical fiber

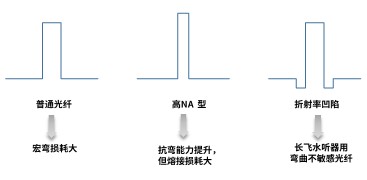

Using the "matched groove" structure design and the unique PCVD process (see Figure 3), can achieve excellent fiber tapering, grinding and bending resistance, and through the use of high reliability coating, guarantee the fiber's high strength and peeling, the main advantages and characteristics of the fiber are as follows:

Figure 3 Optical fiber structure design

1)Fiber thinning

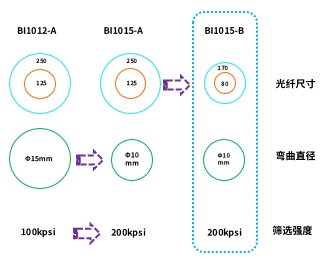

Bend-insensitive optical fibers for hydrophones are currently generally moving towards thinner diameter and high strength. How to reduce the diameter of the optical fiber while ensuring the high strength of optical fiber is a major difficulty. As shown in Figure 4, the minimum bending diameter of the second-generation bend-insensitive fiber is currently designed to be 10mm, and its fiber size has been reduced from 125/250μm to 80/165μm. At the same time, the test strength of the fiber can still be maintained at 200kpsi. In addition, the third-generation products BI1015-F and BI1015-P maintain the thin diameter and high test tension of the optical fiber, and focus on the improvement and optimization of the coating. The use of boiling-resistant materials greatly improves the mechanical stability of the optical fiber.

Figure 4 Bending insensitive fiber

2)Good geometric consistency

Geometrically, the outer diameter tolerance of the fiber coating layer can be controlled within ±2μm and the cladding tolerance within ±1.0μm by precise drawing process control (as shown in FIG. 5), which is crucial for accurate winding and reduction of weld loss.

Figure 5 Optical fiber coating And package statistics

3)Excellent taper pulling performance

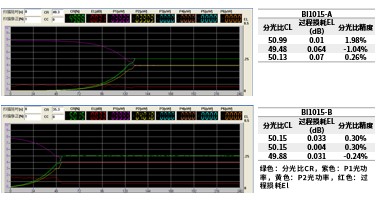

In the tapering performance, by optimizing the fiber waveguide structure and material ratio, The bending insensitive optical fiber for hydrophone has excellent taper pulling performance. Taking the 1550nm50/50 fiber coupler as an example, the tapering performance of the optical fiber is measured and verified according to the process loss of the coupled fiber during the fusion tapering process (see Figure 6).

Figure 6Fiber taper performance verification

4)Reliable mechanical stability

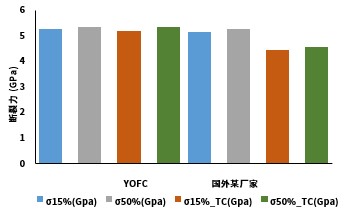

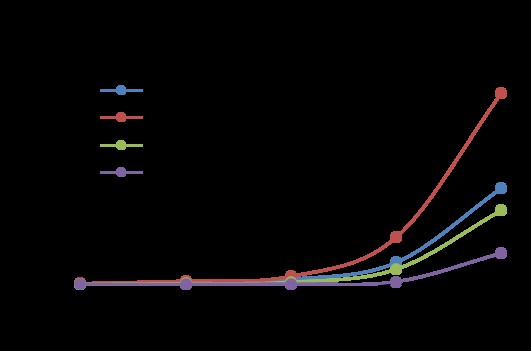

In terms of strength, in addition to meeting the 200kpsi screening, it also performs well in tensile and aging resistance (as shown in Figure 7). For the service life under the bending radius that the customer cares about, we have also carried out comparative verification (as shown in Figure 8). The obtained verification data is derived from the industry's default formula and the service life result far exceeds the customer's requirements.

Figure 7 Breaking force test data of bending-insensitive fiber before and after aging (TC means aging)

Figure 8: Comparison of the break time of bending-insensitive optical fiber at home and abroad under extremely small bending radius

Second, special optical cables for underwater use

Based on the bending insensitive optical fiber, the special optical fiber used in underwater observation network and underwater detection is prepared. The cable can be applied to the maximum water depth of 5000 meters, the cable tension can be customized according to customer requirements, the cable has 6.75Mpa longitudinal water pressure performance. The main products are towing cable, water - tight cable, water - listening cable, etc.

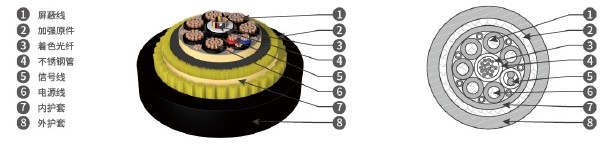

1)Towed cable

The towed cable adopts hydrolyzable polyurethane as sheath protection material, water-resistant aramid as strengthening element, and special flexural high-strength fiber as optical transmission medium. The optical unit and electrical unit can be designed according to customer requirements (see Figure 9). The optical cable can be used for remote control of underwater vehicles and ROV, navigation status monitoring, optical cable for buoys and short distance transmission of large capacity information such as video data.

Figure 9 Schematic diagram of towed optical cable structure

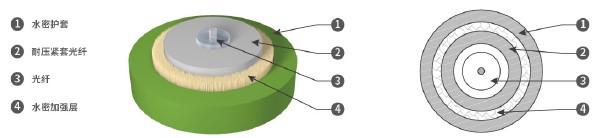

2)Watertight optical cable

Watertight optical cable is used for underwater short distance transmission and can meet the requirements of radial water pressure test. The inner layer is made of high modulus compressive material and the outer layer is made of high density material (see Figure 10). The cable has certain mechanical properties and stable transmission under water pressure. The sheath material used has watertight performance, can long time underwater communication, and has good oil resistance, mechanical properties.

Figure 10 Schematic diagram of watertight optical cable structure

3)Hydrophone Optical Cable

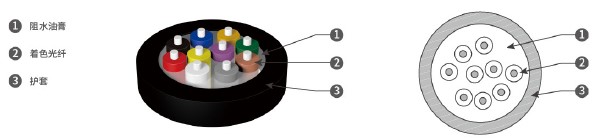

Hydrophone optical cable is used in laying underwater observation network array. It has the advantages of light weight and high flexibility. The cable is made of high strength bending fiber and low hardness polyurethane elastomer (see Figure 11), ensuring that the cable can meet a smaller bending radius to adapt to more complex wiring. Optical cable can be used in different situations of skylight opening at the same time, with oil resistance, hydrolysis resistance, silicone oil resistance, can be used in the water cable array wiring.

Figure 11 Schematic diagram of hydrophone cable structure

3. Outlook

It is the excellent performance of bent insensitive optical fiber that ensures the normal operation of fiber optic hydrophones, so that we can listen to the sound of the ocean. At present, bending-insensitive optical fiber has been applied in the domestic hydrophone industry. With the rapid development of new technology and the iteration of new products in the world, continuous technical efforts have provided a strong guarantee for the overall reliability of optical fiber hydrophone system and made new contributions to China's Marine industry.